IoT Enabling CNC Machines

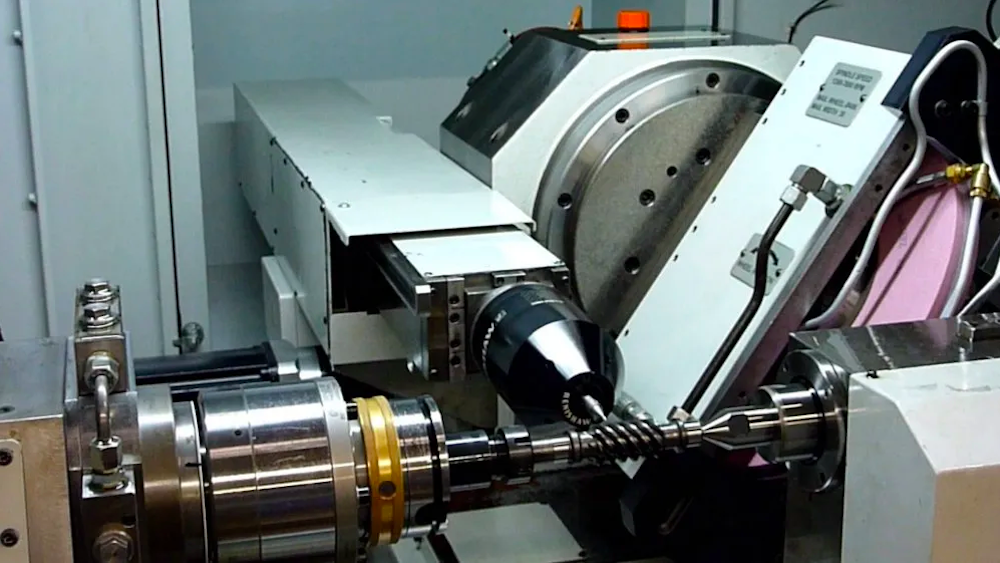

CNC (Computer Numerical Control) machines are widely used in the manufacturing industry to produce complex workpieces in a single operation. CNC machines are multi-tasking and multi-functional machines that use rotating tooling operations such as drilling, tapping, slotting, and milling to turn a workpiece. The occurrence of random failures is closely related to important parameter settings that cause production failure. To overcome this challenge, Azile used IoT technology to enable CNC machines for better production monitoring, live dashboards and reports, and condition monitoring with live alerts.

Challenge: Environment CNC machines are complex machines, and their maintenance requires expertise and resources. The occurrence of random failures in CNC machines is often related to some important parameter settings. CNC machines produce complex workpieces in one operation, and any failure in the production process leads to a significant loss of time and resources. Therefore, it is crucial to maintain the machine’s condition and monitor the production process to ensure smooth and efficient production.

Desired Outcomes: Azile aimed to address the challenge by providing a solution that can analyse production monitoring, generate live dashboards and reports, maintain condition monitoring, and live alerts. Azile also aimed to compare the production plan versus actual production and create a scaled-down version for small and medium customers.

Azile Approach : Azile approached the challenge by utilizing technology to provide services to machine tool manufacturers. Azile offered customization of hardware, firmware, and cloud application solutions to maintain CNC machines. The solutions enabled the following:

- On-Prem and Cloud Application for Smoother Process: Azile provided on-prem and cloud-based applications that allowed for smoother production processes. The applications were customized to the needs of the machine tool manufacturers and enabled real-time monitoring of the production process.

- IoT-Cloud Based Prototype Testing Development: Azile utilized IoT technology to develop a cloud-based prototype that allowed for testing of the CNC machines. The prototype helped identify the issues related to random failures, which helped in optimizing the parameter settings.

- SAAS Based Model for Production Reports Generation: Azile provided a SAAS-based model that generated production reports in real-time. The reports compared the production plan versus actual production and provided insights into the production process. The reports also provided information on the performance of the CNC machines, which helped in identifying potential issues.

Azile successfully utilized IoT technology to enable CNC machines for better production monitoring, live dashboards and reports, and condition monitoring with live alerts. The solutions provided by Azile helped in identifying the issues related to random failures, optimizing parameter settings, and improving the production process. The SAAS-based model provided real-time production reports that compared the production plan versus actual production and provided insights into the production process. The success of Azile’s approach highlights the potential of IoT technology in the manufacturing industry.